Wrightstyle and an Aluminum Anniversary

- By Tim Kempster

- Jul 22, 2015

If it was a wedding anniversary, a traditional gift—albeit somewhat unromantic—would be aluminum, which makes some sense because Wrightstyle supplies glazing systems in both aluminum and steel. However, for us, it’s an even more important anniversary because it was ten years ago that we first introduced a market-leading glazing system that could withstand the pressure impact of a lorry bomb. It was ground-breaking at the time; there were more than a few doubters who said that a glazing system couldn’t resist such an immense blast pressure. But we developed our structurally-glazed system and independently tested it against the equivalent of 500 kilos of TNT (acknowledged to be the explosive impact of a lorry bomb) which is roughly ten times the size of a car bomb.

If it was a wedding anniversary, a traditional gift—albeit somewhat unromantic—would be aluminum, which makes some sense because Wrightstyle supplies glazing systems in both aluminum and steel. However, for us, it’s an even more important anniversary because it was ten years ago that we first introduced a market-leading glazing system that could withstand the pressure impact of a lorry bomb. It was ground-breaking at the time; there were more than a few doubters who said that a glazing system couldn’t resist such an immense blast pressure. But we developed our structurally-glazed system and independently tested it against the equivalent of 500 kilos of TNT (acknowledged to be the explosive impact of a lorry bomb) which is roughly ten times the size of a car bomb.

Known in the industry for developing glazing solutions for challenging specifications, Wrightstyle was initially approached with a set of criteria for the Central Security and Coordination Command Centre for the Asian Games hosted in Doha, Qatar in December 2006. Initially designed to protect and prevent any disruption to the critical operations of the Games’ coordination, the $31 million building also needed to be designed with the intention to hand it over to the Qatar military on completion of the Asian Games. The strict criteria from the project architects and consultants required the majority of the external glazing to mitigate the effects of a medium-sized lorry bomb and a close range car bomb.

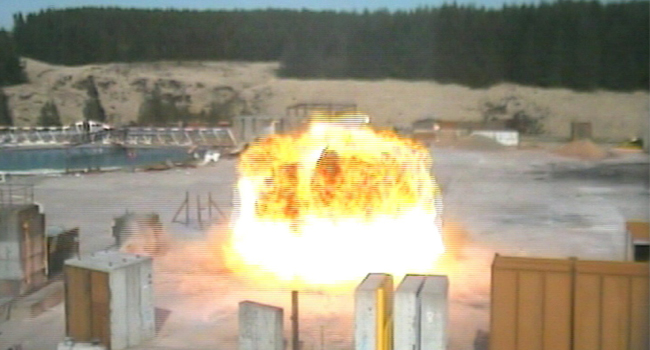

Other requirements were that the glazing have solar control, be thermally performing, and to have an external sight line of less than ¼ inch and internal sightline of less than 2½ inches to maximize vision to the building exterior—project requirements for which there was no tested system available on the market. Our solution was achieved through a high-specification structural glazing technique that bonds the glass to the framing support system so that, in an explosion, the components work together to safely absorb the thermal shock of the explosion. Successful tests were carried out independently by Advantica Limited at a specialist site within RAF Spadeadam, Northumberland. The simulated lorry bomb attack was immediately followed by a simulated car bomb attack (100 kilos of TNT). The lorry bomb was detonated about 250 feet from the test rig and the car bomb was detonated at a distance of over 65 feet, producing a higher loading on the facade.

The Wrightstyle system set a new benchmark for a glazing system to mitigate against blast attack and, with terrorism much in the news, has now been supplied to a number of projects in the United States, UK, and the MENA and Asia-Pacific regions. It is a worldwide success, protecting high-risk buildings and those adjacent to them. We’ve also been pushing the boundaries – for example, to make our advanced system look no different from non-protected glazing systems. Such an achievement deserves more than a lump of aluminum but, being also being a supplier of aluminum glazing systems, we could make good use of it.

About the Author

Tim Kempster is managing director for Wrightstyle.