Media Conversion

Choosing the right backbone

- By Susan Stanley

- Jun 01, 2014

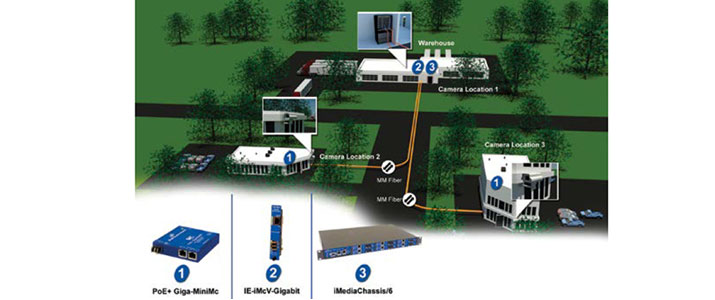

When a successful European toy

manufacturer outgrew its facilities,

it built a new, three-facility

campus that included an

office along with manufacturing

and warehouse space. It would have been impractical

to network the new campus with copper Ethernet

cable, since it has a range limitation of about 100

yards. While that could have been increased to 1,900

yards with Ethernet extenders and DSL technology,

the bandwidth would have been limited at the longer

ranges. Instead, the manufacturer chose multi-mode

fiber as the network backbone.

When a successful European toy

manufacturer outgrew its facilities,

it built a new, three-facility

campus that included an

office along with manufacturing

and warehouse space. It would have been impractical

to network the new campus with copper Ethernet

cable, since it has a range limitation of about 100

yards. While that could have been increased to 1,900

yards with Ethernet extenders and DSL technology,

the bandwidth would have been limited at the longer

ranges. Instead, the manufacturer chose multi-mode

fiber as the network backbone.

Multi-mode is less expensive than single-mode fiber

as it typically employs lower-cost electronics, like

LEDs and vertical cavity surface emitting lasers (VCSELs).

It has a smaller range than single-mode fiber,

which can reach up to 64 miles, but multi-mode can

still carry data several miles at speeds of up to one

Gigabit. Multi-mode shares single-mode fiber’s immunity

to Electromagnetic Interference (EMI), and

both fiber types are inherently secure because the data

travels on a beam of light, meaning outsiders can’t

hack in via Wi-Fi.

Security was an important consideration since

the facility received daily visits from toy sales representatives,

vendors and other outsiders. The factory

owners wanted to establish 24/7 video surveillance

for the campus, but IP cameras are typically installed

in inconvenient locations—you’ll see them on top of

light poles, for example. These cameras need a power

supply of some sort, and because IP cameras usually

have 100 MBps copper interfaces, they would also

need media conversion before they could connect to

the campus’ fiber infrastructure.

Standard copper-to-fiber media converters could

convert the signals from IP cameras, but they wouldn’t

solve the power problem. And, because the cameras

would be outdoors, the company needed media converters

with extended temperature specs, along with

the ability to observe and report faults on remote copper

and fiber connections.

The manufacturer ultimately chose a PoE media

converter, the B&B Electronics PoE+ Giga-MiniMc.

Power over Ethernet (PoE)

While concurrently supporting the Ethernet data

stream, PoE devices greatly simplify installation by

letting network switches and other “injectors” provide

power to connected devices over the Ethernet cable.

This works because a copper RJ-45 cable has four

wires: Two support the data stream, and the other

two are available for PoE. A PoE copper port’s ability

to carry power will not impact or reduce the efficacy

of the data stream. Low-power devices can use Cat-3

cables, but devices that draw more power require Cat-

5, Cat-5e or Cat-6 cables.

There are two types of PoE power sourcing equipment

(PSE) that support point-to-multipoint power

distribution: endspan and midspan. An endspan PSE

is typically a switch and can be placed anywhere a

switch or router would normally be required. Midspan

devices, like PoE-enabled media converters, inject

power inline and are often used when upgrading

an existing network to PoE standards. A midspan device

is placed between an existing legacy switch and a

powered device, which could be an IP camera, a wireless

access point, a serial device server or any other IP

device that requires power.

On initial power up, the PSE is designed to detect

and supply power to only the network devices that it

identifies as being PoE-enabled. The PSE initiates this signature detection process by using low

probing voltages to sense the type of

connected power device. PSEs are able

to detect several undesirable load conditions,

including shorted communications

cables, disconnected powered devices

and the connection of non-PoE devices.

The original IEEE 802.3af-2003

PoE standard provided up to 15.4

W DC—minimum 44 V DC and 350

mA—to each device, with 12.95 W

available at the powered device after

cable loss. But some devices, such as

heated remote cameras, need more.

So, the newer IEEE 802.3at-2009 PoE

standard (referred to as either PoE+ or

PoE plus) nearly doubles the available

power, providing up to 25.5 W while

remaining compatible with the older

802.3af PoE standard.

PoE+ switches and injectors will

recognize 802.3af powered devices and

source power to them accordingly. The

reverse is also true: PoE+ powered devices

will recognize 802.3af PoE injectors

and are designed to restrict how

much power they draw, preventing

damage to the equipment.

With PoE’s low voltage, it is considered

to be safe enough that it doesn’t

bring strict building codes into play,

which lowers installation costs. Note

that AC power standards, plugs and

outlets vary from one region to another,

but PoE equipment works everywhere.

Hot Swappable Transceivers

and Remote Diagnostics

In addition to the twin 10/100/1000

MBps PoE copper ports, the media

converters provided a small form pluggable

(SFP) fiber port. SFP fiber ports

future proof an installation by supporting

both 100 MBps and 1000 MBps connections.

Currently, the toy factory only

requires 100 MBps connectivity to meet

its needs. If, at a later date, the owners

wish to upgrade the system to gigabit

(1,000 MBps), the transition from multimode

to single-mode fiber would be

easy. There would be no need to replace

the media converters; the hot swappable

SFP transceiver is the only component

that would need to be changed.

The media converters provide a useful

diagnostic feature called Link Fault

Pass Through (LFPT). LFPT means

that the state of the 100BASE-TX copper

receiver is passed to the 100BASEFX

fiber transmitter. Imagine a situation

in which a remote device stops

communicating. The LFPT function lets

the media converter detect the lost copper

link and alert the network manager.

By deploying devices that combine

PoE, remote management features and

wide temperature specs, this toy manufacturer

was able to establish video surveillance

in all desired locations while

simultaneously retaining the option to

upgrade to single-mode fiber, should

the need arise.

This article originally appeared in the June 2014 issue of Security Today.