Leveraging Thermal Against Threats

Defending against external threats and asset failure at substations

- By Fredrik Wallberg

- Mar 01, 2019

Artificial intelligence continues to redefine the capabilities

of physical security systems and shape customer

demands. Today, users expect their security solutions

to feature analytics that enable object recognition,

target classification, facial detection along with many

other advanced functions. In other words, end users across the security

industry are searching for systems that provide a return on investment

as well as business intelligence beyond security.

Electrical substations are a prime example. Housing missioncritical

assets in remote locations where activity is mostly static, substation

monitoring can be tedious. However, recent advancements in

intrusion detection technologies and analytics software are helping

substations to leverage thermal imaging cameras to improve both security

and operations. While many utility professionals are familiar

with how thermal cameras can provide 24-hour perimeter monitoring

for threat detection, there is also a key opportunity to deploy thermal

for continuous condition monitoring for machinery. By leveraging

thermal for security and maintenance, utilities deter intruders, prevent

equipment failure, reduce unexpected downtime for customers,

and gain substantial savings.

Why Substations Are Deploying Thermal

When it comes to perimeter protection, there is a reason these highend

assets deploy premium thermal cameras. First, enterprise-grade

thermal cameras deliver consistent performance even in harsh weather

environments. Capturing the minute differences between heat signatures

of objects, thermal cameras produce clear, sharp imagery in

rain, shine or complete darkness. By deploying thermal cameras with

long detection ranges, security directors receive an early warning of

any approaching threat from several hundred meters away.

New multi-faceted cameras featuring both thermal sensors and

optical cameras with built-in analytics are also attractive options

for substations and system integrators alike because they simplify

deployment. Traditional fence protection and buried cable sensor

systems require extensive materials and labor. A standard, eightfoot-

tall chain link fence for a 200 yard area can be upwards of

$50,000. Add that to the costs for trenching, the cable system itself,

and the cameras needed to provide visual verification for any alarm events. In the end, you’re looking at a hefty startup price for

a system that will likely take several weeks to install. On the other

hand, thermal solutions that combine multiple detection technologies

under one housing substantially minimize hardware foot print

and shorten installation time as they can be easily mounted onto

existing structures.

Another key value of high-quality thermal solutions with optical

imagers and embedded classification analytics is that they produce

accurate alarms and video verification. Upon detection, operators

can review both thermal and color video clips to verify alerts before

dispatching police. These technologies effectively reduce false alarms,

which is a key reason why these solutions are so appealing to utilities.

Protection Beyond the Perimeter

As utilities come to the end of implementing solutions like thermal

cameras to satisfy NERC CIP-014 requirements, more companies are

shifting their focus beyond security to asset performance. To distribute

energy to homes, businesses and other facilities each day, it is vital

that substation transformers, lightning arresters, isolators, insulators

and other equipment function optimally.

A common failure for substation equipment is the thermal dynamics,

or the heating and cooling system. If a transformer overheats

and burns, the consequences are severe. The multi-million dollar

transformer could be out of commission, and it could be several

months before it could even be replaced. In the interim, service would

be down, and the interruption in business could cost the utility thousands

of dollars.

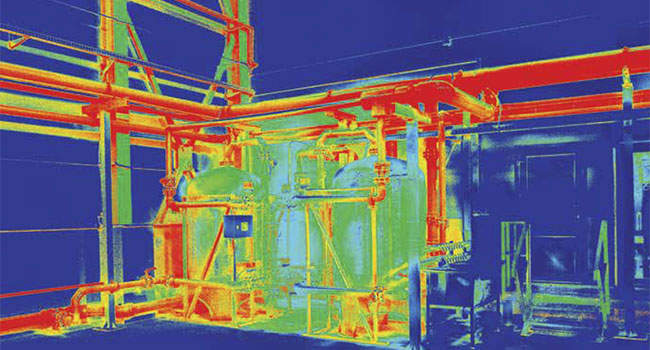

For these reasons, asset monitoring and asset resiliency are critical

for substations. One cutting-edge technology integration substations

are beginning to use to address this need is radiometric (or temperature

measuring) thermal cameras paired with analysis software. This

technology duo allows facility operators to monitor assets, inspect

equipment where the temperature reaches a specified threshold, and

take preventative measures. Here’s how it works, and the features utilities

should look for in radiometric thermal cameras and temperature

trending software.

Thermal for Asset Monitoring

To collect accurate temperature information, a superior thermal imager

is needed. For utilities looking to deploy a fixed or PTZ radiometric

thermal camera, the product should offer non-contact temperature

measurement, integration with external control systems,

and alarming options via email, website or mobile devices. Premium

radiometric thermal cameras will also feature edge analytics for classifying

humans or vehicles.

While the radiometric thermal camera captures data, smart analytics

software is needed to interpret and deliver this information in

a way that is valuable to substation staff. For optimal results, utilities

should deploy an open architecture smart analytics software solution

that aggregates temperature data to video management systems, OSI

PI and SCADA systems.

The function of the smart analytics software is to read, process

and analyze the thermal sensor readings. The software can then generates

reports on temperature trends on an asset over time as well as

temperature trends on all similar assets across multiplies sites. It can

also send an alarm to staff if a component’s temperature exceeds a

pre-set threshold.

Temperature Trending for

Predictive Maintenance

With the ability to collect temperature trending information on assets

in real time, facility managers can identify poor-performing

components. Small changes in temperature on an asset, where the

temperature of its counterparts remains steady, could indicate a

problem that warrants an in-person inspection. Proactive preventative

maintenance can help avoid in-person visits in often frigid and

isolated places.

If further evaluation reveals an asset’s issue cannot be resolved

with repairs, utility staff can collectively decide to replace the

equipment prior to failure. This kind of predictive maintenance reduces

the total cost of ownership for assets, minimizes the number

of unscheduled downtime events, and saves the utility hundreds of

thousands of dollars in the long run. Many energy companies are

adopting security and preventative maintenance solutions and are

seeing great results.

Another key advantage of deploying radiometric thermal cameras

with analysis software is that it improves efficiency during repair

visits. Typically, when a repair is needed on an asset, a thermographer

travels to the substation to first perform an inspection.

Upon arrival, the individual uses a handheld thermal imager to

take temperature measurements to check for load balance before

the equipment is taken offline for repair. The thermographer then

waits for several hours for repairs to the equipment before making

a final assessment to ensure the load is balanced and the equipment

is functioning properly. With radiometric thermal cameras on-site,

a thermographer can remotely scan the component to ensure the

electrical load on the apparatus is balanced across all connections.

The real-time temperature reading and analytics before and after

the repair verifies whether the problem was truly fixed or if the issue

requires further attention.

One of the greatest benefits of a thermal and temperature trending

software solution is the peace of mind it provides to utility staff.

Instead of detecting a transformer burning out, staff can use this

technology to prevent it. By utilities implementing predictive maintenance

systems that reduce the risk of an asset malfunctioning, stakeholders

rest assured that initiatives are being taken to avoid failure

and business losses.

A Complete Solution

Tying it altogether, a typical setup for a substation using thermal for

both perimeter security and asset monitoring would include fixed

thermal analytic cameras along the perimeter, a PTZ radiometric

thermal camera in the center, and radiometric thermal cameras in

high-priority asset areas. Upon detection of a human in an unauthorized

area from the fixed perimeter analytic cameras, the PTZ

camera could track the intruder. Upon validating the alarm, the security

operator could immediately dispatch a guard to the area to

detain and apprehend the intruder before the individual could inflict

any damage.

Meanwhile, the radiometric thermal cameras on-site would continuously

survey all equipment in their purview 24-hours a day, seven

days a week. If a component’s temperature surpasses the threshold

or if temperature trends appear abnormal, operations staff can act to

resolve the issue before the component overheats.

By employing thermal technology and analytics,

utilities gain a complete solution that prevents

intrusion and asset failure and one where the

solution pays for itself, both in value and costsavings.

This article originally appeared in the March 2019 issue of Security Today.